for the past few months the room where i work and listen has been a 11′ x 11′ x 9′ bedroom that my wife and i refer to as our office. basic sheet-rock construction and much need for some acoustic help. after reading for a few weeks on both john sayers forum and a few other sites i decided to build my own treatments. i basically followed the advice most of these guys give and didn’t buy expensive foam absorbers. now i have not installed foam in my room, listened, and then built these and listened again, so i have no real opinion about foam except that most of the guys on the forums think its a waist of money. i know i spent about $300 – $400 building the panels i made and what i’ve been quoted on foam supplier’s sites is easily upwards of $1000. everyone who doesn’t sell foam seems to agree that rigid fiberglas is the way to go.

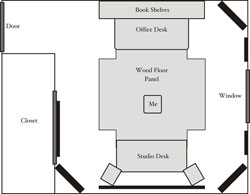

here is the layout of the room and what i wanted to do.

anyone interested in doing a project like this should spend a good deal of time reading john’s forum and this article by ethan winer. the purpose of the panels i built was basically to make the room good for listening to music. i was not at all concerned with keeping sound out or in, but just sounding good.

i followed this thread from john’s forum pretty much throughout with the exception that my corner bass traps are 4″ thick rockwool (basically the same density and material).

i made the frames out of 8′ sections of 1×4 which is actually .75″ x 3.5″ so the 4″ thick rockwool sticks out the back about half an inch.

the midrange panels on the walls have 2″ thick rigid-wrap fiberglass insulation which is used normally in industrial areas. its basically the same as the owens corning rigid fiberglass but with slits cut in it so it can wrap around cylinders in chemical plants. the only reason i used it was because it was a little cheaper and SPI in austin had it in stock. the 1×2’s on the back are just being used to hold the insulation in place. on the bass traps i used three inch srews all the way around into the insulation to hold it in place.

you want to buy fabric that you can breath through easily (meaning sound can pass through as well) and i wanted it to no show through either. i bought grey and dark red jersey knit (t-shirt material) at hancocks for pretty cheap. it’s stretchy too so it was fairly easy to get tight around the panels. i just used a staple gun.

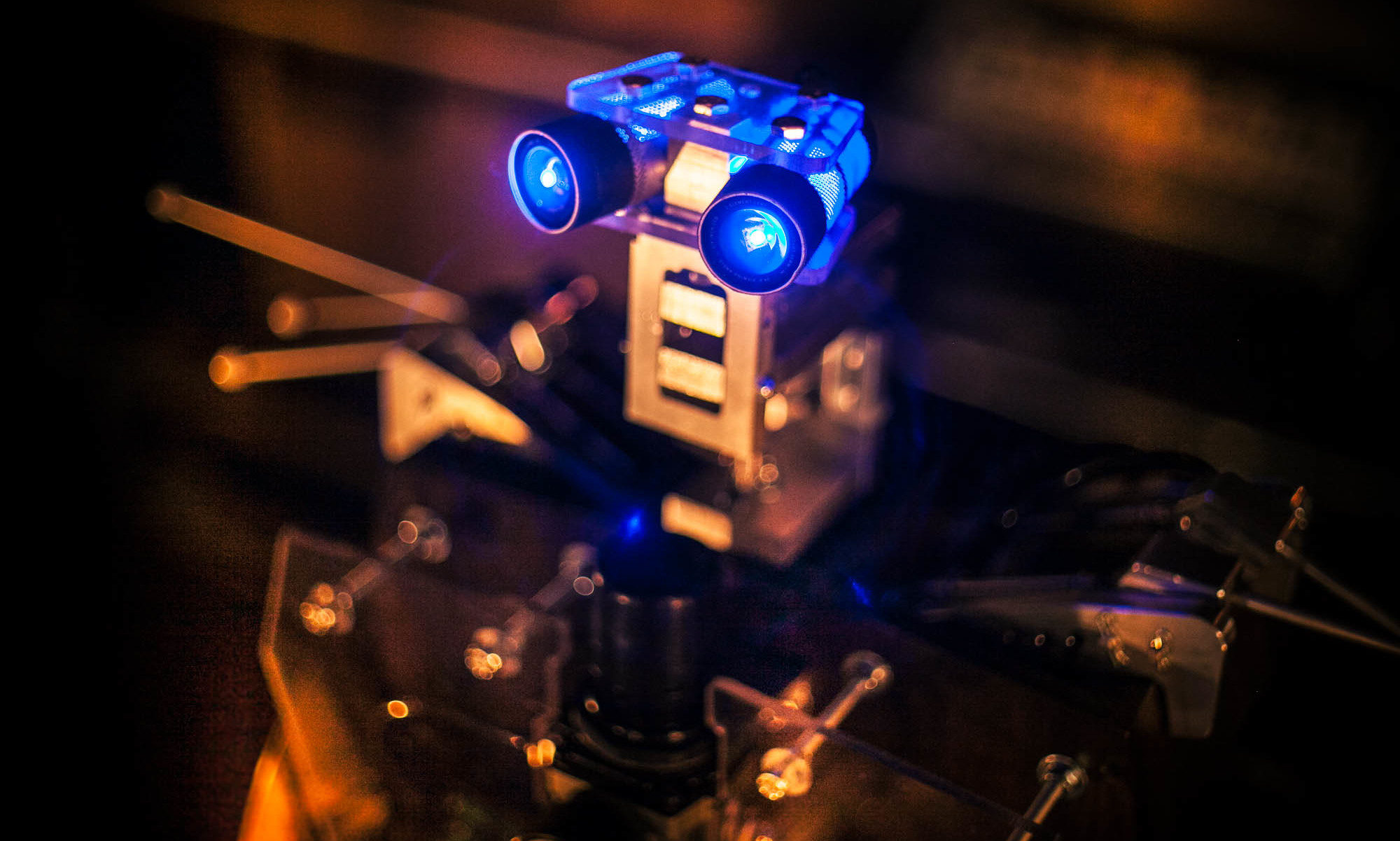

here is the finished room. this is only the one wall that the studio equipment is on.